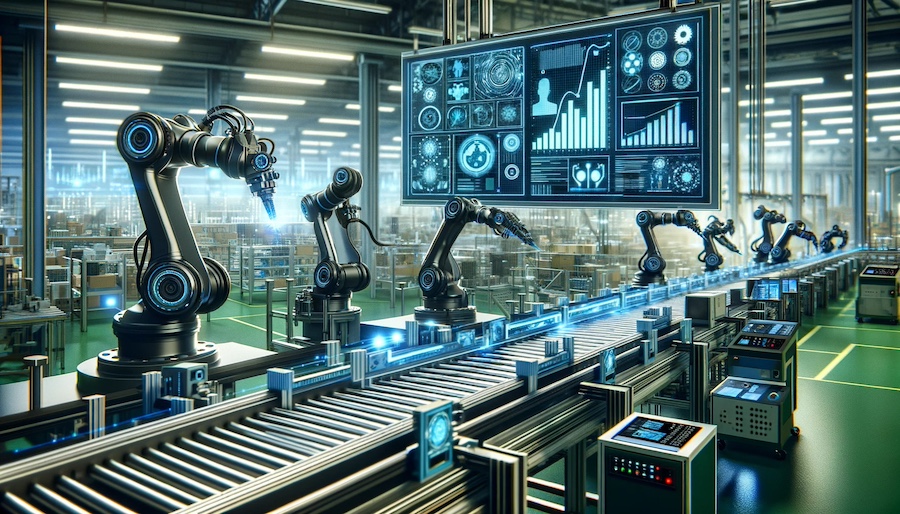

AI-Powered Quality Control and Inspection in Manufacturing

Computer Science

Sawan Prasad

A technology that uses computer vision and machine learning algorithms to automate quality control and inspection in manufacturing, detecting defects and anomalies in real-time.

The technology utilizes a combination of computer vision and machine learning algorithms to automate quality control and inspection in manufacturing. This system consists of several components, including cameras, sensors, and processing units, which work together to detect defects and anomalies in real-time. The cameras and sensors capture images and data from the production line, which are then processed by the computer vision algorithms to detect patterns, shapes, and anomalies. The machine learning algorithms, specifically deep learning models such as convolutional neural networks (CNNs), are trained on large datasets of images to learn the characteristics of acceptable and defective products. The system can be integrated with existing manufacturing equipment and production lines, allowing for seamless inspection and quality control. The real-time processing capabilities enable immediate detection of defects, allowing for prompt removal of faulty products from the production line. This reduces production costs, improves product quality, and enhances customer satisfaction. The technology can be applied to various industries, including food processing, pharmaceuticals, and automotive manufacturing, where quality control is crucial.The computer vision algorithms used in this technology include image processing techniques such as thresholding, edge detection, and feature extraction. These techniques enable the system to enhance image quality, detect edges and boundaries, and extract relevant features from the images. The machine learning algorithms, on the other hand, enable the system to learn from experience and improve its accuracy over time. The system can also be trained to detect specific types of defects, such as cracks, dents, or misaligned parts.The benefits of this technology include improved product quality, reduced production costs, and enhanced customer satisfaction. Additionally, the system can operate in various lighting conditions and can handle complex inspection tasks, making it a robust and reliable solution for quality control and inspection in manufacturing. The technology can also be integrated with other manufacturing systems, such as enterprise resource planning (ERP) and supply chain management (SCM) systems, to provide a comprehensive view of the production process and enable data-driven decision-making.

Predictive maintenance in industries such as aerospace, automotive, and healthcare where equipment failure can have significant consequences, by integrating computer vision with IoT sensor data to detect potential equipment failures before they occur.

Automated inspection in food processing and packaging to detect contaminants, spoilage, or improper packaging, improving product safety and reducing waste.

Real-time monitoring of construction sites to detect safety hazards, track progress, and identify potential structural issues, enhancing site safety and project management.

Quality control in pharmaceuticals to inspect pills, capsules, or vials for defects, contamination, or incorrect labeling, ensuring the integrity of medicinal products.

Defect detection in textiles and apparel to identify fabric defects, uneven dyeing, or stitching errors, improving product quality and reducing manual inspection labor.

Inspection of electronic components and printed circuit boards (PCBs) to detect soldering defects, missing components, or incorrect component placement, enhancing the reliability of electronic devices.

Automated inspection of agricultural products such as fruits and vegetables to detect bruises, decay, or contamination, improving food quality and reducing waste.

Monitoring of infrastructure such as bridges, roads, and buildings to detect cracks, corrosion, or other signs of deterioration, enabling proactive maintenance and enhancing public safety.

Inspection of artworks and historical artifacts to detect forgery, damage, or restoration needs, preserving cultural heritage and supporting authentication.

Real-time quality control in 3D printing to detect layer adhesion issues, incorrect material usage, or print anomalies, ensuring the production of high-quality printed parts.

World Health Organization (WHO)

Artificial intelligence

View Patent