Self-Healing Nanocomposites for Aerospace Applications

Physics

A self-healing nanocomposite material that can repair cracks and damages autonomously, enhancing the durability and safety of aerospace structures

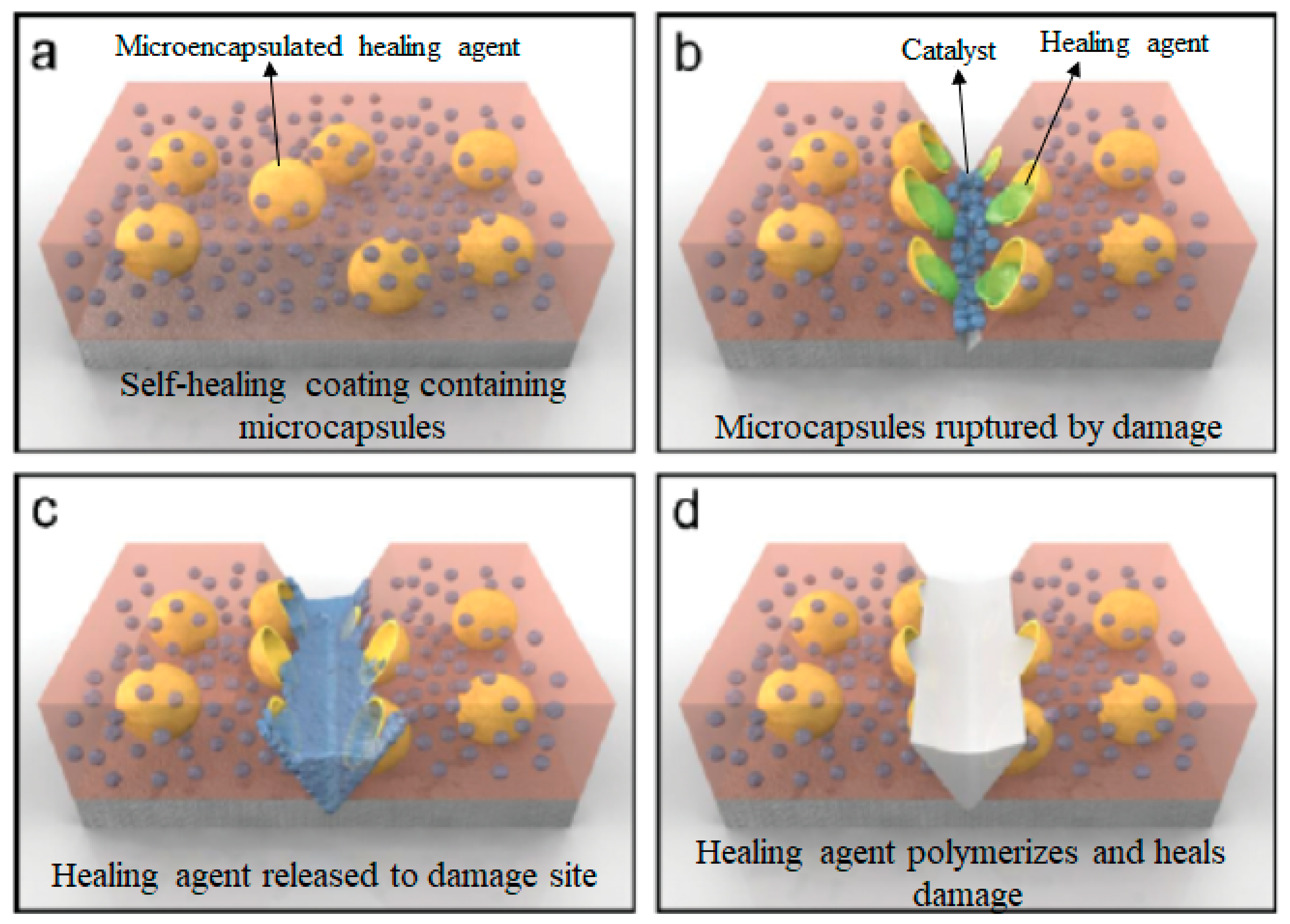

The self-healing nanocomposite material is comprised of a polymer matrix reinforced with nanoparticles and microcapsules containing a healing agent. The polymer matrix provides the structural framework, while the nanoparticles enhance mechanical properties and facilitate the self-healing process. Microcapsules, typically made of a polymer or silica, are dispersed throughout the matrix and contain a low-viscosity healing agent, such as a monomer or oligomer. When a crack or damage occurs, the microcapsules rupture, releasing the healing agent into the damaged area. The healing agent then polymerizes, either through heat, light, or moisture, to form a new polymer that repairs the damage.The self-healing mechanism is based on the concept of microencapsulated healing agents, which was first introduced in the 1990s. The material's autonomic healing capability is enabled by the integration of microcapsules and nanoparticles, which work synergistically to detect and repair damage. The nanoparticles, such as carbon nanotubes or graphene, not only enhance the mechanical properties of the material but also serve as a catalyst for the healing reaction. The self-healing process can be triggered by various stimuli, including temperature changes, light, or mechanical stress.The aerospace industry can greatly benefit from the development of self-healing materials, as they can significantly enhance the durability and safety of aircraft and spacecraft structures. By autonomously repairing cracks and damages, self-healing materials can reduce the need for maintenance and repair, thereby minimizing downtime and extending the lifespan of the structure. Additionally, self-healing materials can improve the structural integrity of aerospace components, reducing the risk of catastrophic failures and enhancing overall safety.The development of self-healing nanocomposite materials involves a multidisciplinary approach, combining expertise in materials science, chemistry, and nanotechnology. Researchers must carefully design and optimize the material's composition, microstructure, and self-healing mechanisms to achieve optimal performance. The use of advanced characterization techniques, such as scanning electron microscopy and X-ray computed tomography, is essential for understanding the material's microstructure and self-healing behavior. Furthermore, the scalability and cost-effectiveness of self-healing materials must be addressed to enable their widespread adoption in the aerospace industry.

Aerospace Engineering: The self-healing nanocomposite material can be used in the manufacturing of aircraft and spacecraft components, such as fuselage, wings, and control surfaces, to improve their durability and reduce maintenance costs.

Damage Prevention in Critical Infrastructure: The material can be applied to critical infrastructure, like bridges, buildings, and pipelines, to enhance their resilience and ability to withstand natural disasters and harsh environmental conditions.

Automotive Industry: Self-healing nanocomposites can be integrated into vehicle body panels and chassis components to reduce repair costs and improve overall vehicle safety.

Biomedical Applications: The material's self-healing properties can be utilized in biomedical implants, such as hip and knee replacements, to improve their lifespan and reduce the need for revision surgeries.

Energy Sector: The self-healing nanocomposite material can be used in the construction of wind turbine blades, solar panels, and other renewable energy infrastructure to improve their durability and reduce maintenance costs.

Marine Applications: The material can be applied to shipbuilding and marine infrastructure, such as hulls, propellers, and offshore platforms, to enhance their resistance to corrosion and damage from marine environments.

Sports Equipment: Self-healing nanocomposites can be used in the manufacturing of sports equipment, like golf clubs, tennis rackets, and bicycle frames, to improve their durability and performance.

Construction Industry: The material can be used in building construction, particularly in high-rise buildings, to improve their structural integrity and resistance to seismic activity.

Robotics and Mechatronics: Self-healing nanocomposites can be integrated into robotic systems and mechatronic devices to improve their reliability and lifespan.

Advanced Composites: The material can be used as a matrix material in advanced composites, such as carbon fiber reinforced polymers (CFRP), to enhance their mechanical properties and damage tolerance.

United Nations Organization (UN)

Proposal

View Patent