Technology Title

AI-Powered Quality Control and Inspection in Manufacturing

AI-Powered Quality Control and Inspection in Manufacturing

Project Title

Implementation of Predictive Maintenance in a Smart Factory

Implementation of Predictive Maintenance in a Smart Factory

Category

Computer Science

Computer Science

Authors

sawan@yopmail.com

sawan@yopmail.com

Short Description

A project to implement predictive maintenance in a smart factory using AI and IoT sensors, reducing equipment downtime and increasing overall productivity.

A project to implement predictive maintenance in a smart factory using AI and IoT sensors, reducing equipment downtime and increasing overall productivity.

Long Description

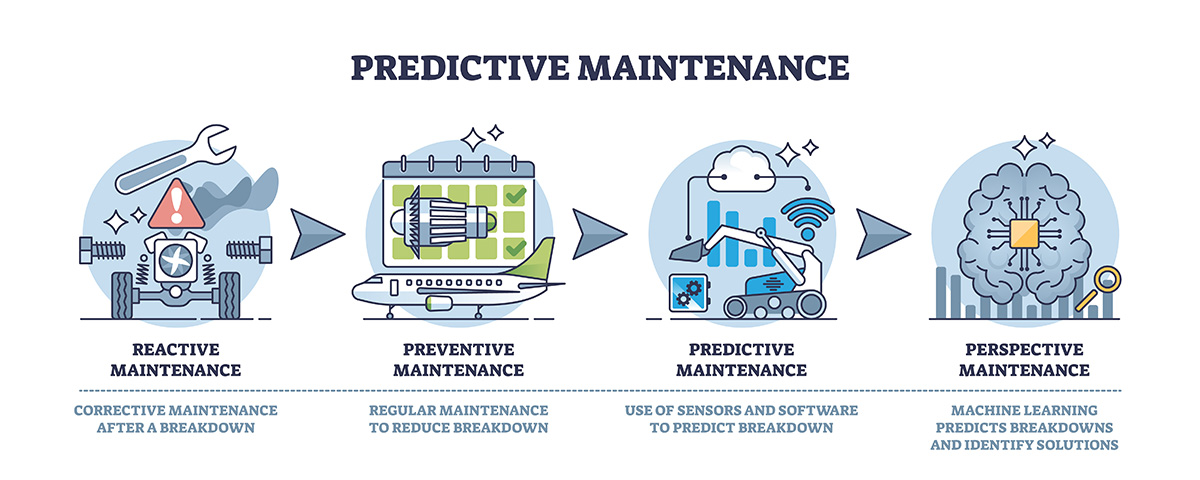

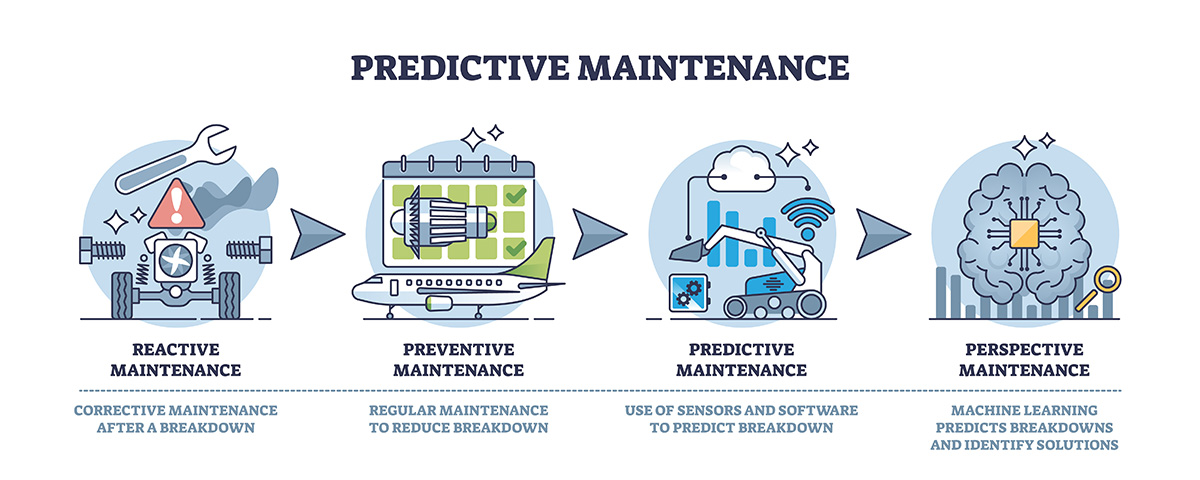

The project involves integrating Artificial Intelligence (AI) and Internet of Things (IoT) technologies to implement predictive maintenance in a smart factory. The goal is to reduce equipment downtime and increase overall productivity. The first step is to install IoT sensors on critical equipment and machinery to collect real-time data on performance parameters such as temperature, vibration, pressure, and energy consumption. These sensors will transmit data to a centralized data processing platform.The collected data will be processed and analyzed using machine learning algorithms to identify patterns and anomalies that may indicate potential equipment failures. The AI system will use historical data, real-time data, and predictive models to forecast equipment failures and schedule maintenance accordingly.The predictive maintenance system will be integrated with the factory's existing maintenance management system to automatically schedule maintenance activities and alert maintenance personnel of potential issues. The system will also provide real-time alerts and notifications to factory operators and managers in case of critical equipment failures or unexpected changes in equipment performance.The AI system will continuously learn and improve its predictive capabilities by incorporating new data from various sources, including maintenance records, equipment specifications, and sensor data. This will enable the system to refine its predictions and optimize maintenance schedules, reducing equipment downtime and increasing overall productivity.The project will also involve implementing data security measures to protect sensitive equipment and production data. This will include encrypting data in transit and at rest, implementing secure authentication and authorization protocols, and ensuring compliance with relevant data protection regulations.The expected outcomes of the project include a significant reduction in equipment downtime, increased overall productivity, and improved resource allocation. The project will also provide valuable insights into equipment performance and maintenance needs, enabling data-driven decision-making and optimization of factory operations.Key technical components of the project include IoT sensors, data processing and analytics platforms, machine learning algorithms, predictive modeling, and maintenance management system integration. The project will require collaboration between data scientists, IoT experts, and factory operations personnel to ensure successful implementation and ongoing operation of the predictive maintenance system.The project timeline will involve several phases, including planning and design, IoT sensor installation, data collection and analysis, AI system development and testing, and integration with the maintenance management system. The project will also involve ongoing monitoring and evaluation to ensure the predictive maintenance system is meeting its performance goals and making adjustments as needed.

The project involves integrating Artificial Intelligence (AI) and Internet of Things (IoT) technologies to implement predictive maintenance in a smart factory. The goal is to reduce equipment downtime and increase overall productivity. The first step is to install IoT sensors on critical equipment and machinery to collect real-time data on performance parameters such as temperature, vibration, pressure, and energy consumption. These sensors will transmit data to a centralized data processing platform.The collected data will be processed and analyzed using machine learning algorithms to identify patterns and anomalies that may indicate potential equipment failures. The AI system will use historical data, real-time data, and predictive models to forecast equipment failures and schedule maintenance accordingly.The predictive maintenance system will be integrated with the factory's existing maintenance management system to automatically schedule maintenance activities and alert maintenance personnel of potential issues. The system will also provide real-time alerts and notifications to factory operators and managers in case of critical equipment failures or unexpected changes in equipment performance.The AI system will continuously learn and improve its predictive capabilities by incorporating new data from various sources, including maintenance records, equipment specifications, and sensor data. This will enable the system to refine its predictions and optimize maintenance schedules, reducing equipment downtime and increasing overall productivity.The project will also involve implementing data security measures to protect sensitive equipment and production data. This will include encrypting data in transit and at rest, implementing secure authentication and authorization protocols, and ensuring compliance with relevant data protection regulations.The expected outcomes of the project include a significant reduction in equipment downtime, increased overall productivity, and improved resource allocation. The project will also provide valuable insights into equipment performance and maintenance needs, enabling data-driven decision-making and optimization of factory operations.Key technical components of the project include IoT sensors, data processing and analytics platforms, machine learning algorithms, predictive modeling, and maintenance management system integration. The project will require collaboration between data scientists, IoT experts, and factory operations personnel to ensure successful implementation and ongoing operation of the predictive maintenance system.The project timeline will involve several phases, including planning and design, IoT sensor installation, data collection and analysis, AI system development and testing, and integration with the maintenance management system. The project will also involve ongoing monitoring and evaluation to ensure the predictive maintenance system is meeting its performance goals and making adjustments as needed.

Potential Applications

Predictive maintenance in smart factories can be applied to various industries such as manufacturing, automotive, aerospace, and food processing, where equipment downtime can be costly and impact production schedules.

Implementation of AI-powered predictive maintenance can also be extended to other areas such as energy management, water treatment plants, and transportation systems, where early detection of equipment failures can prevent major disruptions.

The use of IoT sensors and AI algorithms can be applied to medical equipment in hospitals, reducing the risk of equipment failure and ensuring that life-saving devices are always operational.

Predictive maintenance can also be applied to wind turbines, solar panels, and other renewable energy sources to optimize energy production and reduce maintenance costs.

In the oil and gas industry, predictive maintenance can be used to monitor equipment condition and predict potential failures, reducing the risk of accidents and environmental damage.

The application of predictive maintenance can also be extended to building management systems, monitoring HVAC, electrical, and plumbing systems to optimize energy efficiency and reduce maintenance costs.

In the transportation sector, predictive maintenance can be applied to vehicles, trains, and airplanes, reducing downtime and improving overall safety.

The use of AI and IoT sensors can also be applied to agricultural equipment, monitoring condition and predicting potential failures, reducing downtime and improving crop yields.

Predictive maintenance can be applied to data centers, monitoring equipment condition and predicting potential failures, reducing downtime and improving data security.

The application of predictive maintenance can also be extended to smart cities, monitoring and managing infrastructure such as roads, bridges, and utilities, to optimize maintenance and improve public safety.

Predictive maintenance in smart factories can be applied to various industries such as manufacturing, automotive, aerospace, and food processing, where equipment downtime can be costly and impact production schedules.

Implementation of AI-powered predictive maintenance can also be extended to other areas such as energy management, water treatment plants, and transportation systems, where early detection of equipment failures can prevent major disruptions.

The use of IoT sensors and AI algorithms can be applied to medical equipment in hospitals, reducing the risk of equipment failure and ensuring that life-saving devices are always operational.

Predictive maintenance can also be applied to wind turbines, solar panels, and other renewable energy sources to optimize energy production and reduce maintenance costs.

In the oil and gas industry, predictive maintenance can be used to monitor equipment condition and predict potential failures, reducing the risk of accidents and environmental damage.

The application of predictive maintenance can also be extended to building management systems, monitoring HVAC, electrical, and plumbing systems to optimize energy efficiency and reduce maintenance costs.

In the transportation sector, predictive maintenance can be applied to vehicles, trains, and airplanes, reducing downtime and improving overall safety.

The use of AI and IoT sensors can also be applied to agricultural equipment, monitoring condition and predicting potential failures, reducing downtime and improving crop yields.

Predictive maintenance can be applied to data centers, monitoring equipment condition and predicting potential failures, reducing downtime and improving data security.

The application of predictive maintenance can also be extended to smart cities, monitoring and managing infrastructure such as roads, bridges, and utilities, to optimize maintenance and improve public safety.

Image

Keywords

First Choice, Second Choice, Third Choice, Proposal, Data

First Choice, Second Choice, Third Choice, Proposal, Data

Email

sawan@yopmail.com

sawan@yopmail.com